Greetings, as the autumn breeze ushers in a fresh season, we extend our heartfelt wishes for the sustained success and growth of your esteemed company.

We deeply appreciate the exceptional support you have always provided. Now, we are pleased to announce that our company will be participating in the “IPF JAPAN 2023 (International Plastic Fair)” as per the details below. We understand your schedules may be busy, yet we warmly invite the relevant members of your teams to visit our exhibit. Below, you’ll find details about the exhibition and our showcased offerings for your convenience.

About IPF:

The largest specialized manufacturing exhibition in Japan focusing on plastics and rubber. Covering all processes related to plastics and rubber from raw materials to recycling, this exhibition gathers industry professionals from around the world once every three years.

Exhibition Details

| Dates | :November 28, 2023 (Tuesday) to December 2, 2023 (Saturday) |

| Time | :10:00 AM to 7:00 PM (Until 4:00 PM on the last day) |

| Venue | :Makuhari Messe, Hall 5 |

| Booth Number | :51618 |

How to Visit

Please pre-register on the official website before your visit.

Pre-register from here: Visitor Registration | IPF Japan|The Plastic Show

Venue Map

Exhibited Machines

Aisa Automation Industrielle SA is a Swiss-based company and the global leading supplier of equipment offering innovative laminate and seamless plastic tube packaging production solutions. It is today the largest manufacturer of machines in its category worldwide. Founded in 1962 and based in Vouvry, Switzerland, AISA holds several patents and has invested heavily in advanced packaging-related technology research and development and strives to maintain its position as a leader in its field.

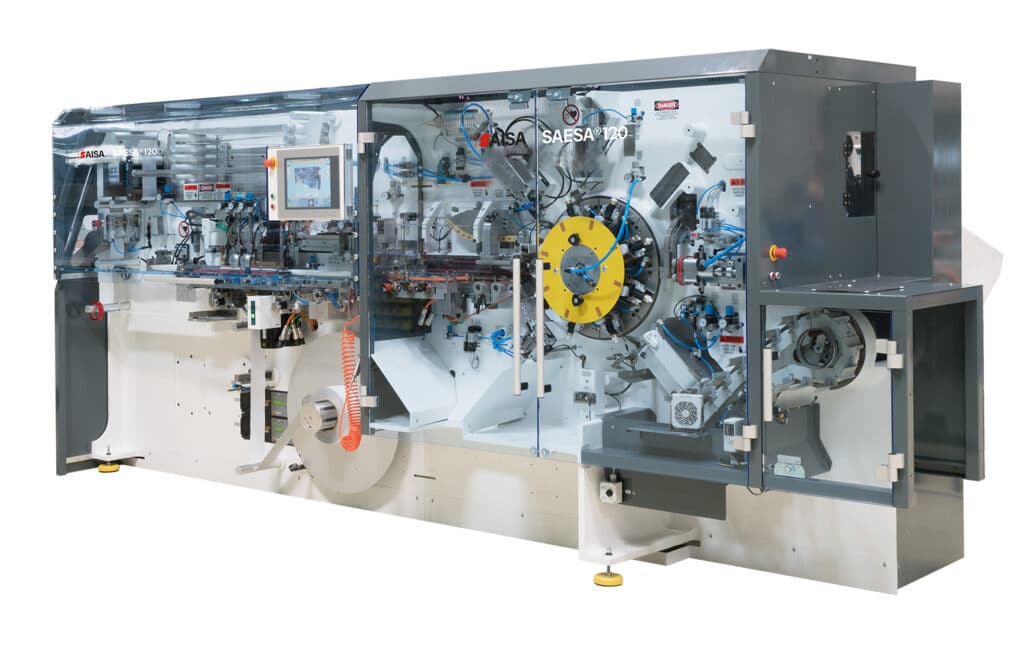

SAESA® 120 Laminate Tube Production Line

The SAESA® 120 from AISA is a high-performance machine designed for mass production. It is equipped with a Double Belt Heat Sealing (DBHS) system for seam welding, capable of welding both ABL and PBL materials. Separate provision for shoulders and caps is available, enabling the use of parts formed separately through processes like injection molding. Depending on the shape, it’s possible to weld caps integrated with shoulders. This presents opportunities for reducing labor and material costs. Leveraging these strengths, it becomes possible to develop and produce a diverse and innovative range of containers.

Manufacturer that produces hot stamping machines, capping inspection machines, and cassers. The company is characterized by its ability to make machines based on experience gained through OEM work for European manufacturers.

TPclassicP Fully Automatic Tube Cartoning Machine

The machine packages tubes into RSC (flap) type or lidded type boxes, regardless of the presence of a plastic bag. It has a high box holding capacity, allowing the use of somewhat deformed boxes. It’s possible to evenly distribute tubes across each row, or place a different number of tubes in each row. The tooling conveyor is specially designed to ensure the stability of the tubes, featuring a compact design that allows for easy changeover.

OMSO is a curved surface printing machine manufacturer boasting over 40 years of sales achievements in the domestic market. Their Servo Series printing machines, developed with an understanding of user needs in new model development, are distinctive. They have a broad range of experience in container printing, including tubes, bottles, cups, and caps.

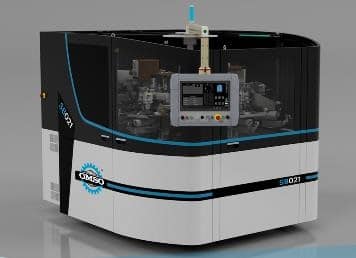

SB021 Servo-Assisted Screen Printing Machine for Bottles

A new screen printing machine for bottles has been introduced by the Italian curved surface printing machine manufacturer OMSO. By reducing the fixture and adopting advanced control through servo motor assistance, the changeover time is significantly shortened. For curing the printing ink, the latest LED UV lamp technology is utilized. The cost reduction achieved by using LED also contributes to CO2 reduction, making this printer essential in the rapidly advancing era of decarbonization.

*Only sample presentation will be available during the exhibition period.

Since its establishment in 1893, IWK Corporation has been dedicated to the development and technological advancement of tube filling and packaging machines. Currently, holding numerous patents relating to key technologies, they continue to provide efficient and highly precise tube filling and packaging machines for the pharmaceutical and cosmetics industries worldwide, through active investment in research and development.

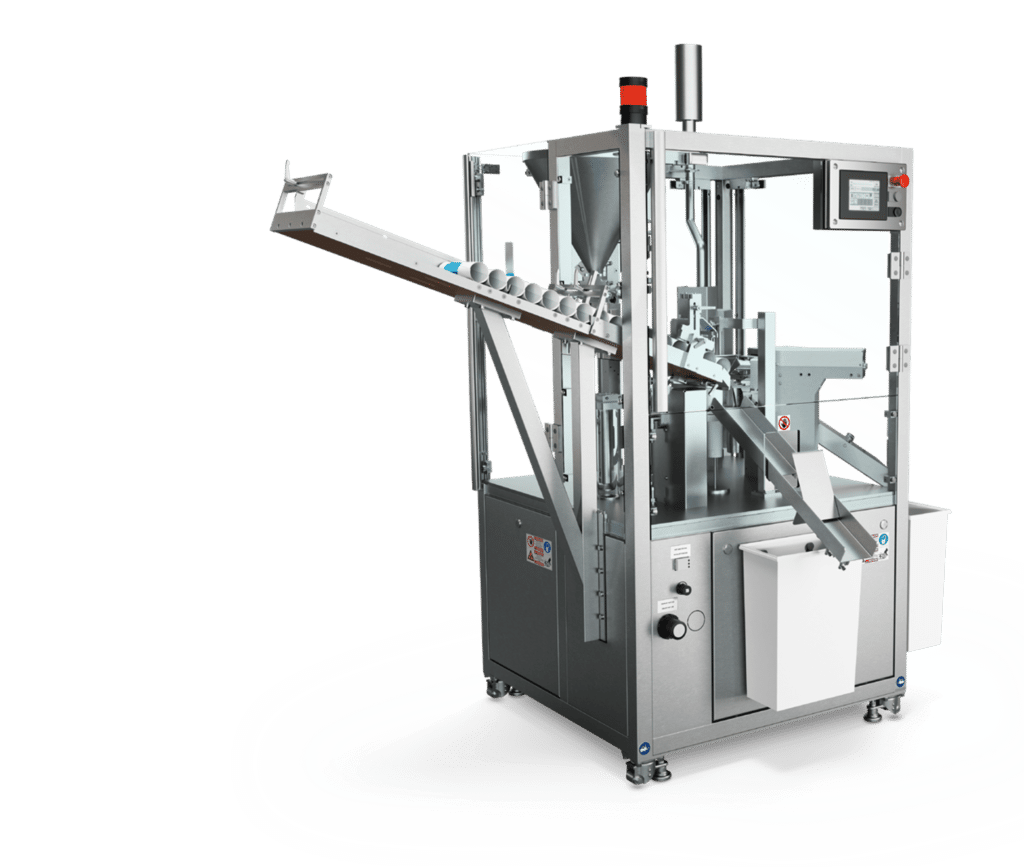

FP8 Tube Filling Machine

The FP8 is an ideal low-speed filling machine for small batch production, delivering a capacity of up to 40 bottles per minute. Upgrades are easily achievable as per requirements, and it excels in operation as a lab machine. Delivery is possible within a minimum of two months from the order. It incorporates the highly durable cutting-edge technology of IWK.

For any questions about the exhibition, please feel free to contact us.