Winckler will exhibit at the 25th INTERPHEX JAPAN [Pharmaceuticals] [Cosmetics] Exhibition. Please take this opportunity to see the latest industrial machinery.

Exhibition Overview

Period: July 5 2023 Wednesday to July 7 2023 Friday

Time: 10:00〜17:00

Place: Tokyo Big Site East Wing

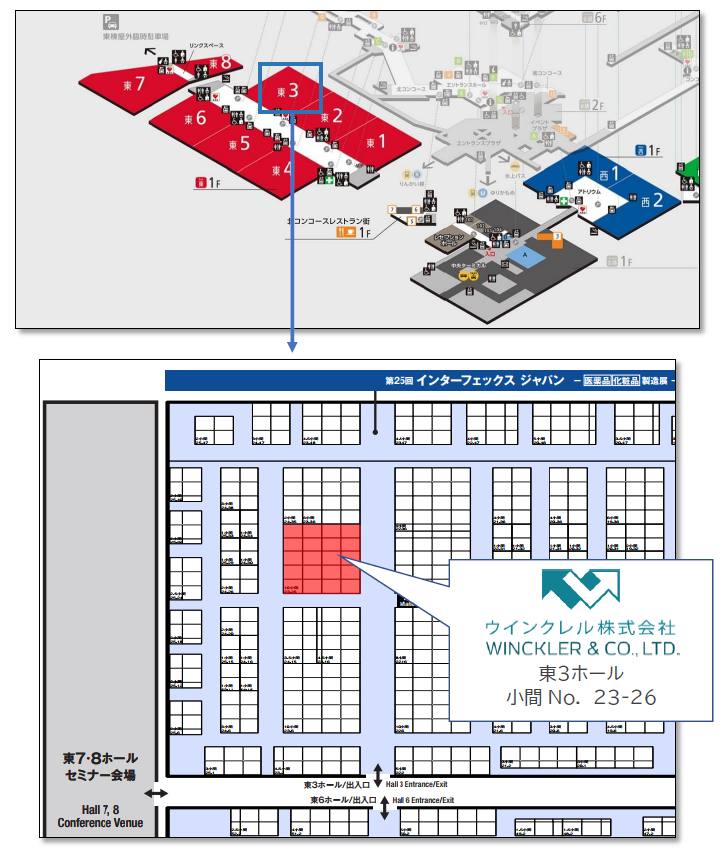

Hall: East 3

Booth: 23-26

※Invitation tickets are required for admission. Please apply in advance here.

Location

Overview of Exhibiting Manufacturers and Machines

GRONINGER & CO. GMBH, Germany

GRONINGER & CO. GMBH is a top manufacturer of liquid filling machines for the pharmaceutical industry, specializing in injectables and eye drops. It also manufactures filling machines for liquid and high-viscosity formulations in the cosmetics industry, such as creams and perfumes. Among its products, it takes pride in its delivery record for filling machines for pre-sterilized containers (syringes, vials, cartridges), including in Japan and worldwide.

LABWORX Series

The LabWorx by GRONINGER & CO. GMBH is their latest benchtop machine composed of four standardized modules: filling, stoppering, capping (peristaltic pump or rotary piston pump). These benchtop machines are primarily used for research and development, clinical trial processes, small-batch filling, and process development for high-speed GRONINGER lines. LabWorx is designed with servo motors and can be controlled through tablets or smartphones.

LABWORX Lab-scale Filling Machine

LABWORX Lab-scale Vial Crimper

(*Detailed information will be provided once confirmed.)

KORSCH AG, Germany

KORSCH AG is a specialized manufacturer of tablet presses in Germany. It offers tablet presses for various types of tablets, including single-layer, multi-layer, enteric-coated, and chewable tablets. It also provides solutions for containment/WIP (highly potent substances containment), smart factory (Pharma 4.0), and data acquisition and analysis tools for tablet presses to meet diverse needs.

XL100 PRO Small Rotary Tablet Press

The XL100 PRO is a robust and compact tablet press with an integrated control panel, ideal for product development. It features excellent accessibility with a corner column-free compression zone, and the turret can be easily exchanged, offering high flexibility. It is designed for easy cleaning and quick changeover, making it suitable for small to medium-scale production.

MEDELPHARM, France

MEDELPHARM is a tablet press manufacturer specialized in the field of research and development. Its tablet presses are equipped with software that allows for data acquisition and detailed analysis, providing innovative solutions for research and development from both mechanical and software aspects.

STYL’ ONE EVO (Research and Development Tablet Press Simulator)

The STYL’ ONE EVO allows for easy investigation and analysis of tablet properties, making it ideal for early tablet characterization, formulation development, and scale-up. It covers various tablet formats, including mono-layer, bi-layer, and up to five-layer tablets. It is a superior tablet press simulator with two modes: displacement mode to simulate rotary tablet presses and compression force mode to produce tablets at pre-set compression forces.

STYL’ONE NANO (Research and Development Tabletop Tablet Press Simulator)

This compact tabletop unit allows for quick characterization with minimal setup and a small amount of raw materials. It is equipped with four types of tablet profiles: single, V-shape, pre-pressure/main-pressure, and square.

IWK VERPACKUNGSTECHNIK GMBH, Germany

Since its establishment in 1893, IWK has been dedicated to the development and improvement of tube filling and packaging machines. They currently hold numerous patents related to key technologies and continue to provide efficient and high-precision tube filling and packaging machinery for the pharmaceutical and cosmetics industries worldwide through active research and development.

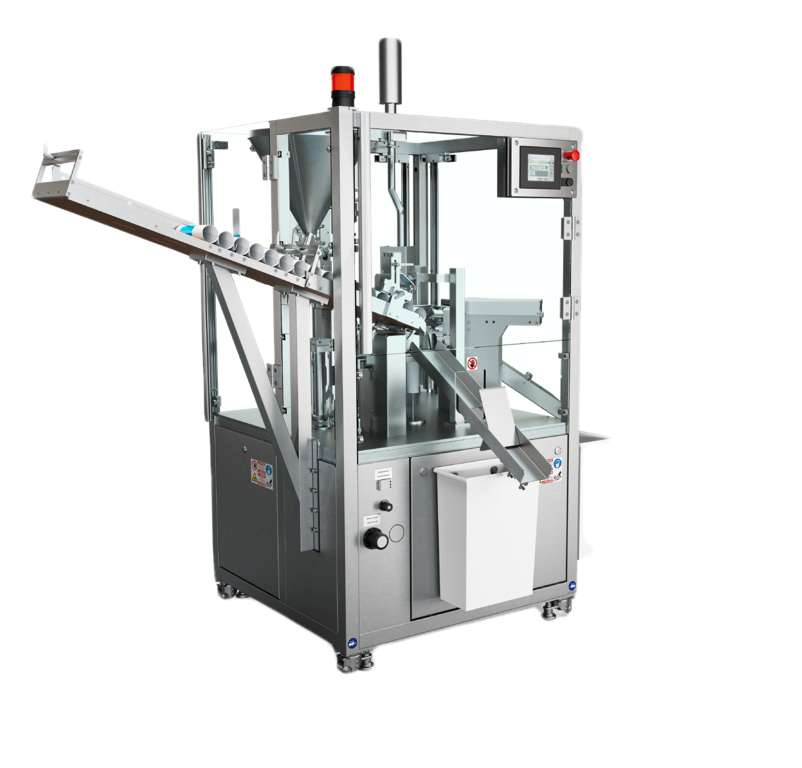

IWK FP8 Tube Filling Machine

The FP8 is a low-speed range filling machine ideal for small-batch production, capable of achieving a maximum capacity of 40 tubes per minute. It offers easy upgrades and excellent operation as a lab machine. Delivery can be made in as short as 2 months from order placement. It incorporates IWK’s highly durable state-of-the-art technology.

IWK FP10 Tube Filling Machine

The FP10 is a single-nozzle tube filling machine capable of achieving a maximum capacity of 70 tubes per minute. By adopting servo-driven motors, it allows for precise filling by freely adjusting filling cam curves and sealing time. The tube sealing unit of the exhibition machine employs a hot air method compatible with plastic and laminate tubes. It also features a format parameter saving function, enabling the storage and retrieval of key settings for each format, contributing to improved production reproducibility and reduced operator workload.

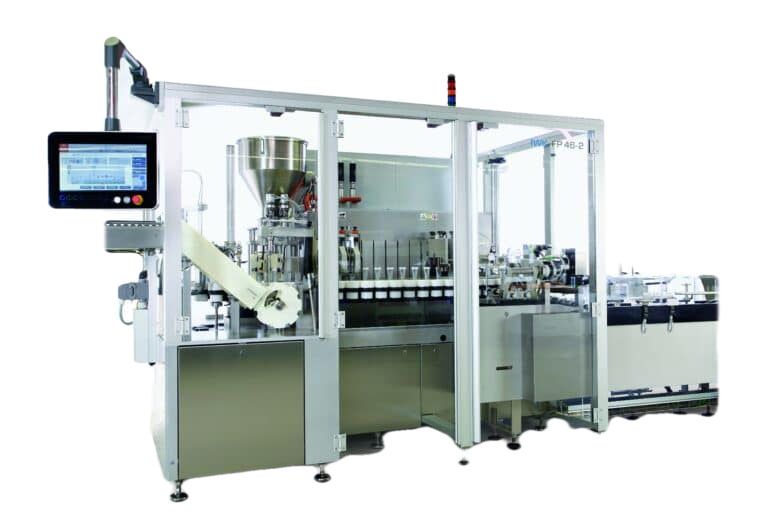

IWK FP34-1 Tube Filling Machine

The FP34-1 exhibits a maximum capacity of 120 tubes per minute and prevents tube markings by securely transporting tubes through its unique conveying system. It can handle various tube materials such as aluminum, laminate, and plastic without the need to replace the hot air or folding units, resulting in reduced changeover time and improved production efficiency. All drives are equipped with servo drives, enhancing positional accuracy, achieving high filling precision, and minimizing product losses. The design allows for the attachment of additional systems such as inspection camera systems to vacant stations easily. It is equipped with an embossing inspection camera, which is useful for tube quality control.

A.BERENTS GMBH&CO.KG, Germany

BECOMIX, the high-quality emulsification machine brand that meets high standards. Known for its performance in efficiently and effectively suctioning powders with its Powder Jet technology, it contributes to the manufacturing of high-quality products. It is a trusted manufacturer with over 2,000 deliveries to leading companies and small and medium-sized enterprises in over 60 countries.

BECOMIX Vacuum Emulsifier RW2.5 Model (Tank maximum capacity: 3.5 liters)

The RW2.5 is a tabletop vacuum emulsifier of the smallest scale in the BECOMIX series for research and development purposes. It is equipped with the same mechanisms as production machines, allowing research and development utilizing the characteristics of BECOMIX with small amounts of raw materials and enabling smooth scale-up.

BECOMIX Vacuum Emulsifier RW15CD Model (Tank maximum capacity: 24 liters)

The RW15 is a tabletop vacuum emulsifier of the BECOMIX series for research and development purposes. It is equipped with the same mechanisms as production machines, allowing research and development utilizing the characteristics of BECOMIX with small amounts of raw materials and enabling smooth scale-up.

BECOMIX Vacuum Emulsifier RW60CD Model (Maximum batch capacity: 60 liters)

The RW60CD vacuum emulsifier is a multi-mixer suitable for pilot plants and production plants in the cosmetics and pharmaceutical industries, with the ability to handle various products ranging from high viscosity to low viscosity and high shear to low shear. It incorporates correlating mechanisms such as homogenizers and anchor agitators with production machines, enabling easy scale-up. With CIP specifications, it achieves reproducible cleaning performance, contributing to improved sustainability.

Weckerle Machines, Germany

Weckerle Machines is a global leader in the field of color cosmetic filling machines. In the early 1970s, Weckerle developed the world’s first fully automatic machine for lipstick and obtained a patent. Since then, they have introduced cutting-edge devices for filling foundations, powders, nail polish, deodorant sticks, cosmetic pencils, lip balms, stick adhesives, and various types of fillings.

The MM series offers a variety of machine modules that enable heated filling of lipsticks and lip balms in various shapes, diameters, and output capacities. It allows for scale-up from small batches or lab production to large-scale production with MM 60, MM 180, and MM 360. Additionally, the MM series enables a flexible lipstick filling process with tool-less changeovers.

*Sample presentation only.

MESPACK, Spain (Pouch Packaging Machines)

Mespack, based in Barcelona, Spain, has the largest product portfolio in the industry, offering horizontal and vertical FFS machines for pouches, sachets, stick packs, and water-soluble pods used in the packaging of food, beverages, pharmaceuticals, chemicals, pet food, confectionery, cosmetics, and personal care products. With sales network teams in over 90 countries, they ensure immediate and efficient supply of machine parts, minimizing lead time.

They provide services in collaboration with leading global brands in the food, beverage, pharmaceutical, chemical, pet food, confectionery, cosmetics, and consumer packaged goods markets. Additionally, they develop innovative technologies to help customers reduce the consumption of raw materials through the introduction of recycled materials and biodegradable materials. Their efforts actively contribute to the Sustainable Development Goals (SDGs).

*Sample presentation only.

AISA, Switzerland (Tube Forming Machines)

AISA is a research and development company within a holding group, actively supporting sustainable development. With innovative patented tube forming technologies such as DecoSeam and Decoplas, they contribute to the creation of new markets.

It will exhibit the latest paper laminate tube that successfully reduces plastic usage by 75% through AISA’s tube forming technology. It is dedicated to developing containers that can be recycled along with paper packaging. AISA is also a machinery manufacturer with a proven track record in sustainable projects such as monomaterial tubes.

*Sample presentation only.

OMSO, Italy (Curved Surface Printing Machines)

OMSO is a curved surface printing machine manufacturer with over 40 years of sales experience in Italy. Their servo series printing machines are distinctive for understanding user needs in new model development. It has a wide range of container printing experience, including tubes, bottles, cups, and caps.

Latest Servo-Assist Screen Printing Machine for Bottles

OMSO, an Italian curved surface printing machine manufacturer, introduces the latest screen printing machine for bottles. It significantly reduces changeover time through the elimination of fixtures and advanced control assisted by servo motors. The printing ink curing utilizes state-of-the-art LED-UV lamps, resulting in reduced running costs and CO2 emissions. This printing machine is essential for the rapid decarbonization trend of the future era.

*Sample presentation only.

Please visit the Interpack exhibition website for more information.