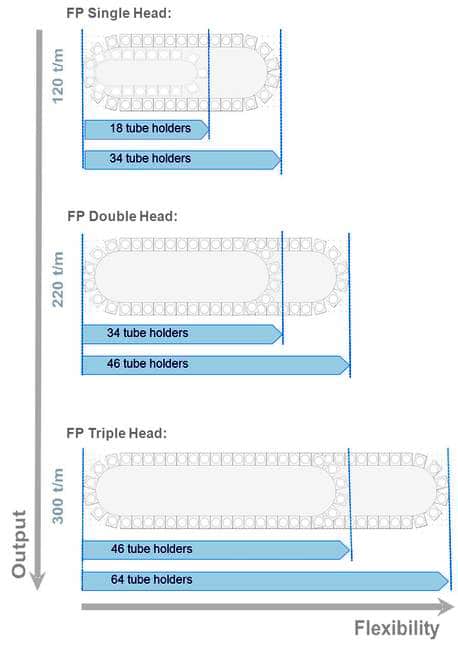

Tube Filling Machine Configurations

The FP Series has several machine configurations available.

Additional Options:

- Code scanning at print registration

- Tube dedusting

- Camera monitoring of tube edge, particles in tube, tube cap presence

- Laminar flow and/or sterile applications

- Different hoppers, Pressure cylinder or tank

- Level monitoring

- Multi color filling

- Change on block of product contact parts

- Rotary lobe pump for CIP / Wash out

- Gas purging, Droplet dosing

- Heated pressing jaws for metal tubes

- Hot-air or high frequency welding

- Tube closing for contour seals

- Double, triple or saddle fold for metal tubes

- Labeling (Embossing, Laser-, Ink-jet-printing)

- Automatic central lubrication

- In-line Check weighing